Originally used to cheaply and quickly make prototypes, 3-D printing has lately gained momentum as a (cheap, quick) manufacturing endpoint in and of itself.

The technology is used for architecture, industrial design, automotive and aerospace engineering, the military, civil engineering, fashion and food. Innovations in different industries have made 3D printers more resourceful that the creators initially intended. it is revolutionizing how we care for one another, though there are still practices that are remarkably outdated or fall short of the goal of improving, or saving, lives, improving customer experiences and improving education.

Considering Health improvements, makers of professional 3D printers are specifically developing, and promoting, dental uses for 3D-printed technology, the universe of non-dental, medical applications are now entering a phase of rapid growth. Now, with the rapid evolution of additive fabrication — the increasingly popular technologies often referred to as 3D printers — the future of health care is advancing in ways both familiar and dramatically new.

Professional 3D printers now incorporate photo-curable resins of various textures, transparency and flexibility — so before procedures, surgeons can now plan complex surgeries with CT scan data of a patient’s bone, blood vessels or other organs, converted to a 3D-printable digital file that can be manipulated and studied. And for operations involving cutting or drilling into skeletal structures — such as jaw surgeries, knee replacements and other joint-related procedures — 3D printing is also creating the perfect fit through printed custom guides and tools.

Using medical imaging and 3D-modeling technology, doctors can now also use 3D printers to create temporary tools that are affixed to the skeletal structure of the patient to provide a precise “blueprint” for reshaping the bone structure to perfectly accommodate standard-size implants. Custom-printed drilling guides ensure that the screws are placed precisely to ensure the best fit with a patient’s body.

Even for people who don’t own a printer, functional prosthetic hands have suddenly become a possibility — including children who would otherwise have struggled through childhood, as kids outgrow prosthetics in just months. And, prosthetics can incorporate custom designs unique to each patient. A number of very happy children are currently using hands modeled after their favorite superheroes.

Moving on to Consumers, someone with a printer can print a child’s new device in less than 24 hours. Non-replaceable devices and gadgets can now get replaced instantly with access to the prototype files from manufacturers. Consumers can now print replacement parts in the comfort of their homes.

In Education, companies are moving to develop models that help children with calculation and constructive IQ modeling at a very young age with the help of 3D machines. It would be very easy for Educational institutions to customize materials to individual students’ needs with the aid of 3D printers and avoid the cost of single Learning blocks purchases that can mean more spending.

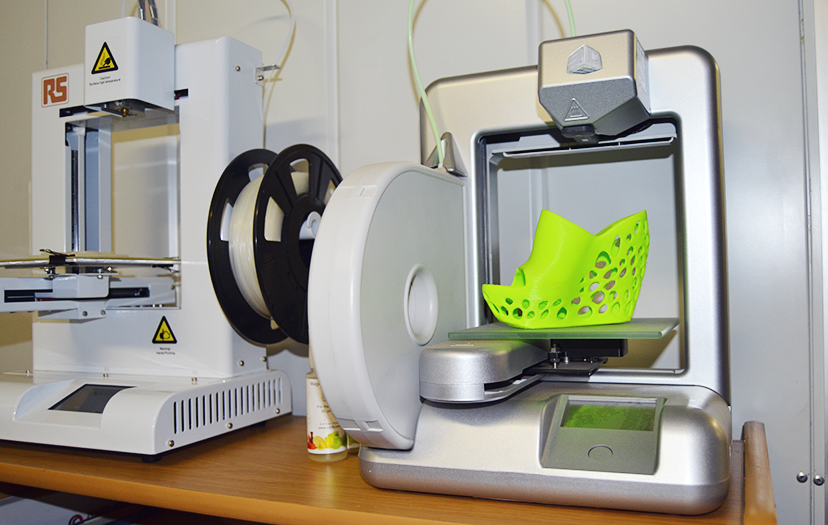

We visited RS Components in Midrand to check the various 3D printers in the Industry, their Impact and how their investment in 3D printers has been improving business standards for their clients and the way it would change the way consumers view 3D printing in South Africa in years to come. Brian Andrew of RS component’s says ” Interest in 3D printing has grown, mostly because of devices that are capable of creating small products or scale models that can be used for design processes” This has increased the interest in 3D modelling at the household consumption level.

3D printing is a growing market and there are few retailers of the consumer-grade 3D printers that can be used by ordinary consumers with minimal knowledge of 3D software. RS component offers support and information on 3D components and services.